Soft Power: An Important Proposition in Building China into a Strong World Manufacturing Power

Nov 15,2001

Li Yan& Wang Zhonghong

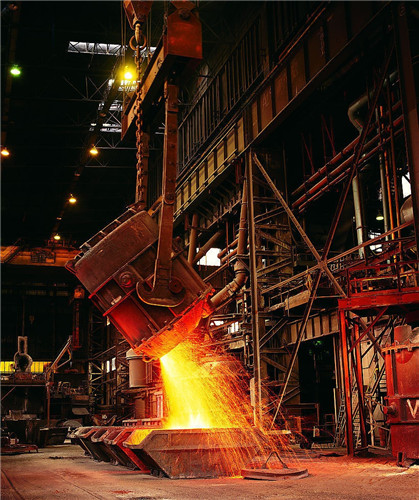

China is already a big manufacturing country, but not yet a strong manufacturing power. The gap between China and early industrialized countries like the U.S., Germany and Japan does not simply lie in hard power such as equipment, energy efficiency and resource utilization, but also in what is called “soft power”. Compared with hard power, soft power is a key ability based on core elements like knowledge, information, skills and culture, supported by industrial spirit, value idea, and institutional environment, and featured by industry innovation ability, quality and service level, brand influence and the leading role in implementing international rules. It embodies the industrial competitiveness, international influence and control ability, as well as the product attractiveness of a country. In view of various countries around the world, it can be found that all the strong manufacturing powers are largely supported by strong soft power. For instance, the industrial spirit of Germany, the mass production mode of Ford and the management mode of Taylor, as well as the lean management mode of Toyota. Soft power has enabled these countries to maintain a persistent leading position in global manufacturing sector.

As one of the core elements of soft power, knowledge capital can promote manufacturing innovation and total factor productivity. Advanced manufacturing is a typical technology- and knowledge-based intensive industry. Intellectual property, also known as intangible assets, will determine the future of manufacturing development. Furthermore, a new round of industrial revolution has facilitated the extensive integration of information technology with manufacturing industry, thus enhanced the value of soft power with big data as its core asset. With the innovative application of industrial networks and intelligent manufacturing, the value-creating ability of manufacturing as a whole will embrace a comprehensive upgrading. This means China should seize the opportunity and push forward the transformation and upgrading of manufacturing competitiveness through soft power enhancement.

At present, the soft power of China’s industry still faces a number of weak points. First, the development and transformation of innovation assets are still weak. As for China, the number of patent applications and the number of granted patents in the world are much less than that of strong world manufacturing powers, and China is lagging far behind in some important fields of technology like optics, engine and transportation, with relatively less name brands in the world. Second, business management level in China is quite low. Some advanced ideas and methods like “lean management” is not widely accepted in China, and there is much room for improvement in normalized management as well as the applicationof advanced ideas in wider areas and at higher levels. Third, the ability to transform the mode of production with the help of information technology is still weak. China’s manufacturing enterprises are still plagued by inadequate investment in some important assets such as information and data, thus the majority of these enterprises remain in phase 2.0 or 3.0. Fourth, the quality of manufacturing professional is yet to be improved. Nowadays, China is in sore need of inter-disciplinary talents in some areas, innovative tech talents, and senior technicians particularly. Fifth, industrial spirit and civilization creation are yet to be advocated. The development pattern of some of China’s manufacturing sectors is too extensive, lacking the shared values and the spirit of the times related to manufacturing, such as the concept of quality, the spirit of honesty and craftsmanship.

At this point, we offer the following options for enhancing China’s soft power. First, we should comply with the “Internet Plus” concept, explore and form smart production mode and service mode actively. By giving full play to the comparative advantages of China’s internet and manufacturing industry, the integration of information technology and manufacturing technology will be further deepened. Second, we should improve the inclusive policy support system to stimulate asset development and achievement transformation. Through the improvement of relevant policies in tax, R&D (research & development) expenditure, and skills recognition, we should design a support system of financing together with an industrial design base to support the development of service industry. Third, we should enhance the management level of enterprises, and promote the transformation of IT application and sophisticated management. With government taking the leading position, we should improve the common sharing services of innovative knowledge as well as engineering data, and improve quality supervision system. Fourth, we should lay emphasis on the enhancement of personnel quality, promote the transformation of human resources into human capital. We should not only carry out the plan for cultivating engineers, as well as the project of updating the knowledge of professionals, but also learn from the dual system vocational education mode in Germany. Fifth, we should cultivate manufacturing culture with Chinese characteristics. We should promote Chinese craftsmanship among employees, advocate team spirit and healthy competition culture among the enterprises, and combine Chinese culture with the image of made in China. And sixth, we should enhance China’s communication capability so as to improve the image of “Made in China”. We should take the opportunity of implementing the “One Belt and One Road” initiative, take past experience in foreign communication into account, and strengthen the introduction of the concept of innovative, coordinated, green, open and shared development to increase the attractiveness of “Made in China”.